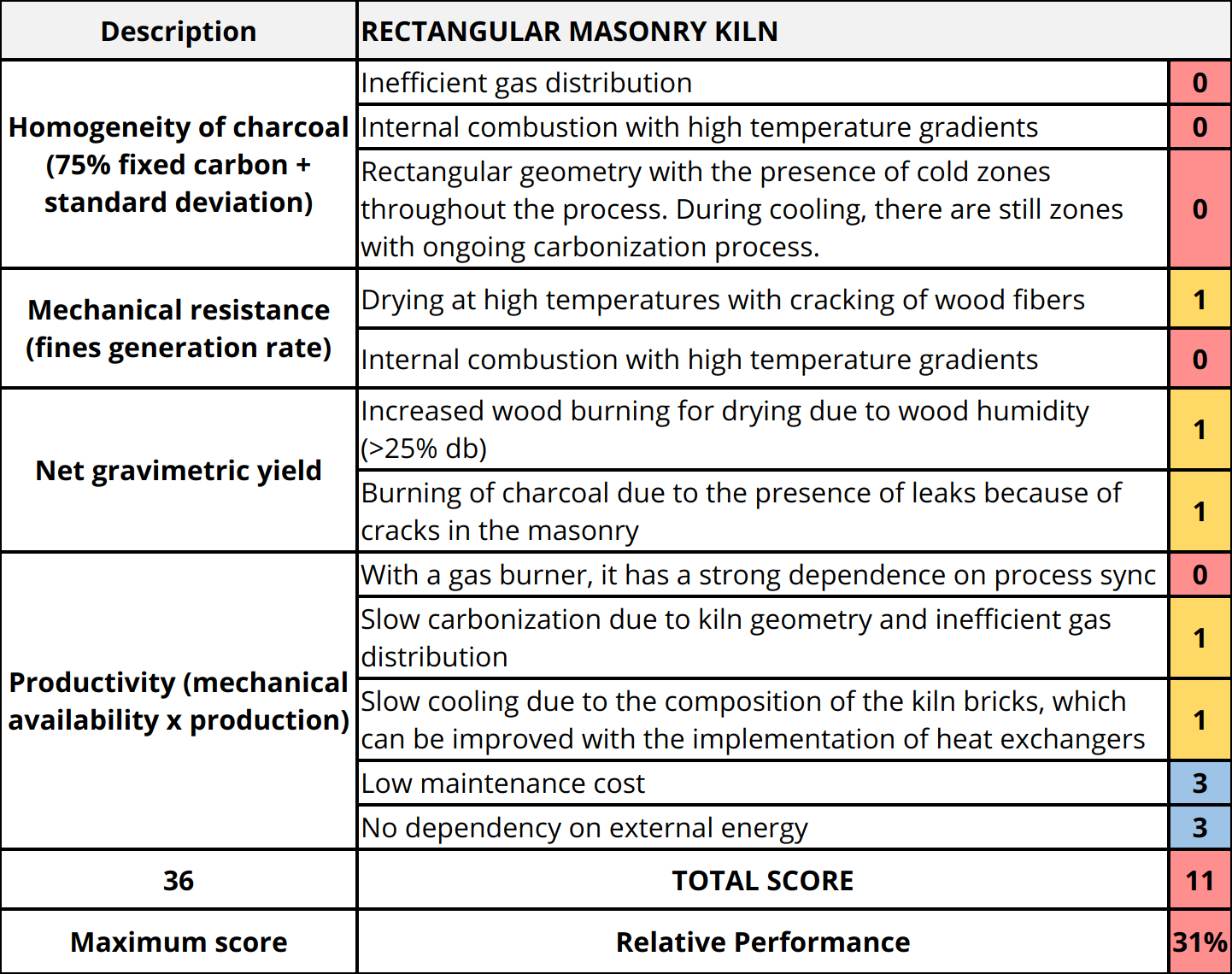

| Description | RECTANGULAR MASONRY KILN | ||||

| Homogeneity of charcoal (75% fixed carbon + standard deviation) | Inefficient gas distribution | 0 | |||

| Internal combustion with high temperature gradients | 0 | ||||

| Rectangular geometry with the presence of cold zones throughout the process. During cooling, there are still zones with ongoing carbonization process. | 0 | ||||

| Mechanical resistance (fines generation rate) | Drying at high temperatures with cracking of wood fibers | 1 | |||

| Internal combustion with high temperature gradients | 0 | ||||

| Net gravimetric yield | Increased wood burning for drying due to wood humidity (>25% db) | 1 | |||

| Burning of charcoal due to the presence of leaks because of cracks in the masonry | 1 | ||||

| Productivity (mechanical availability x production) | With a gas burner, it has a strong dependence on process sync | 0 | |||

| Slow carbonization due to kiln geometry and inefficient gas distribution | 1 | ||||

| Slow cooling due to the composition of the kiln bricks, which can be improved with the implementation of heat exchangers | 1 | ||||

| Low maintenance cost | 3 | ||||

| No dependency on external energy | 3 | ||||

| 36 | TOTAL SCORE | 11 | |||

| Maximum score | Relative Performance | 31% | |||

WavenTech. Technology

WavenTech. Technology

Carbonization x Pyrolysis

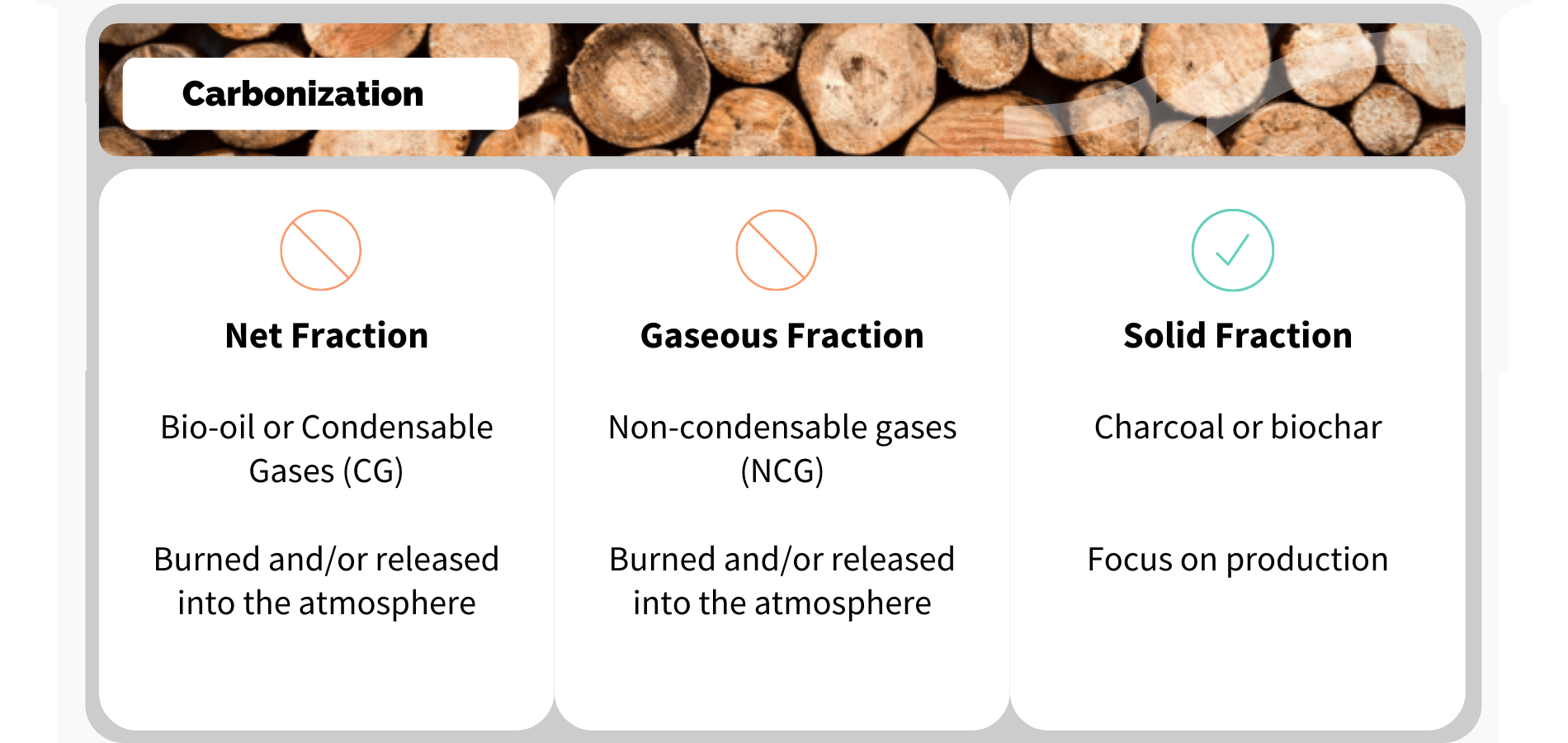

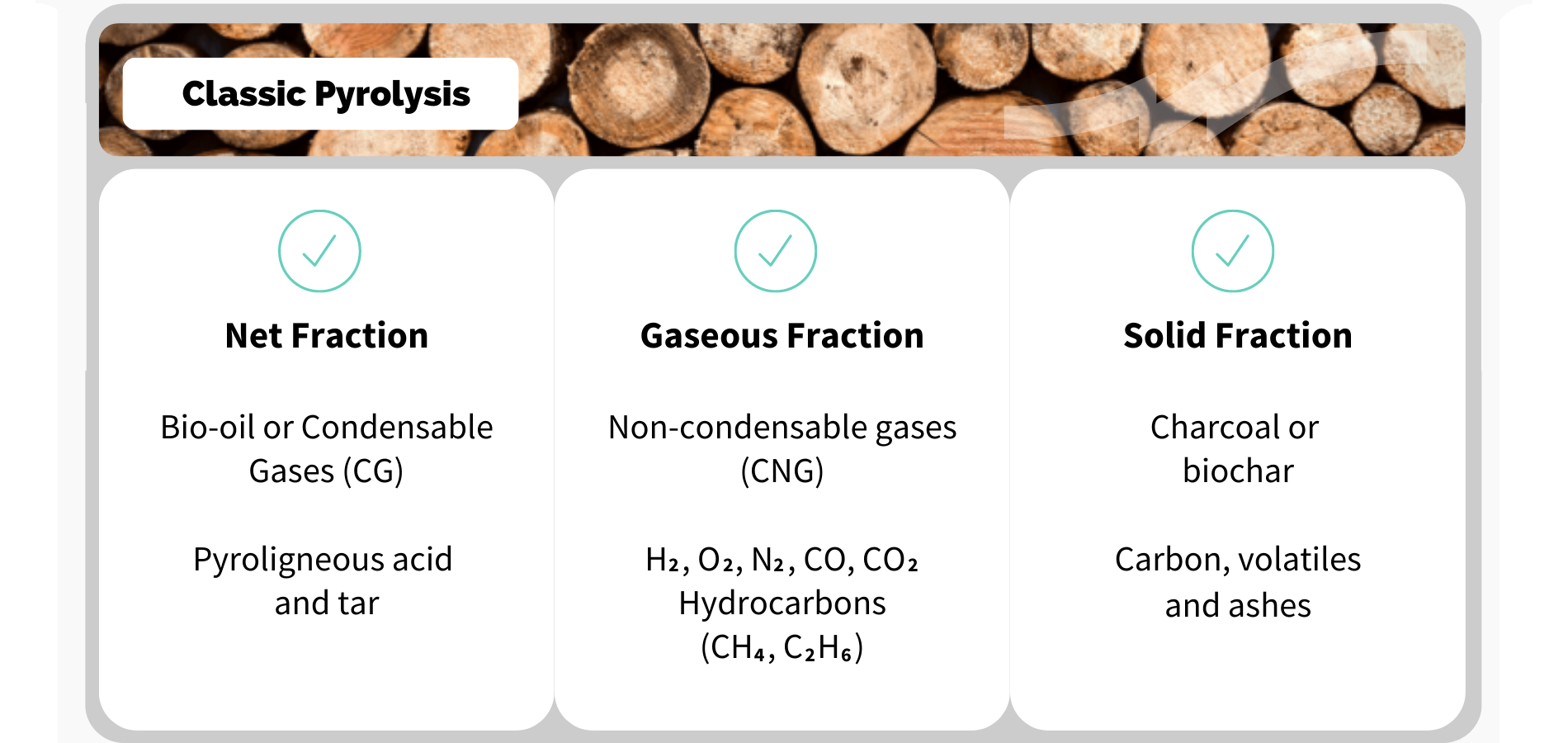

To understand the differentials of the technology, it is necessary to understand the advantages of carrying out pyrolysis in relation to simple carbonization.

Pyrolysis (from the Greek pyr, pyrós = fire + lysis = dissolution) is an analysis or decomposition reaction that occurs by the action of high temperatures, with the rupture of the original molecular structure of a certain compound (in this case, wood or biomass) by the action from heat in an environment with little or no oxygen.

Basically, with pyrolysis we can recover and use the liquid and gaseous fractions resulting from the reaction, which in carbonization are burned and/or simply released into the atmosphere (=smoke). Thus, the role of WavenTech. technology is to provide an ideal environment for this reaction, obtaining solid, liquid and gaseous fractions in the desired quantities.

That’s the beauty of our solution!

WavenTech. solutions matrix

WavenTech. Technology

Traditional Method x WavenTech. Technology

Before a technical explanation, we present contrasting images, in relation to 4 aspects that mark this difference:

Before

Before

After

After

Industrial activity x rural activity

Before

Before

After

After

Professional handling x poor handling

Before

Before

After

After

Automated process x strong dependence on labor

Before

Before

After

After

Mathematical modeling x subjective evaluation

As you can see, the difference is significant.

The differentiation will be even more evident with the technical approach, from the explanation below.

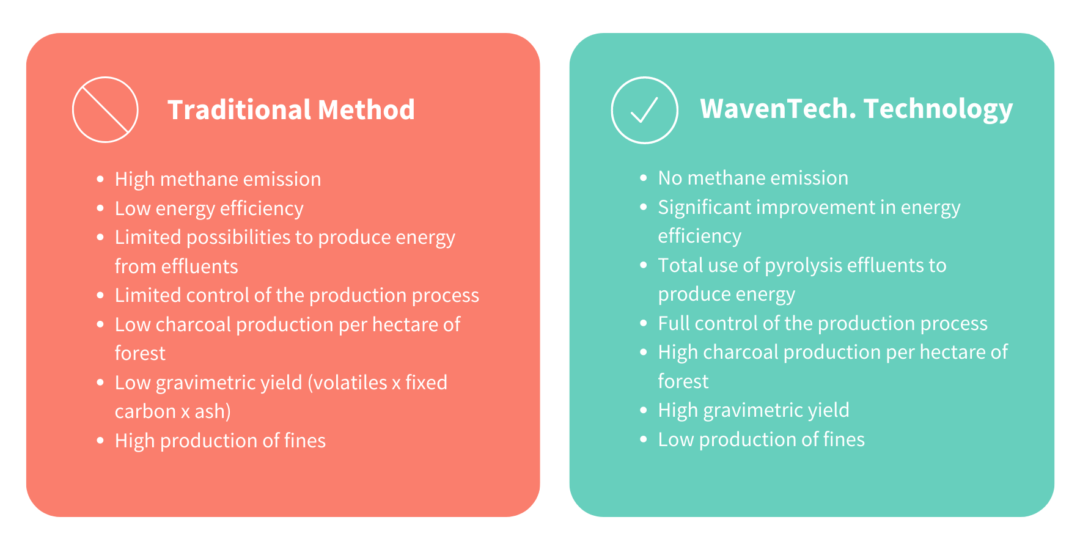

The microwave-assisted pyrolysis technology provides for the elimination of environmental impacts and the energy recovery of effluents, transforming them into sustainable electricity and contributing to the reduction of charcoal costs for 3 reasons:

Part of the wood does not need to be used as fuel

Full conversion of effluents into electricity, with a capacity much greater than consumed (Brayton/Rankine combined cycle)

Lower investment in fixed assets

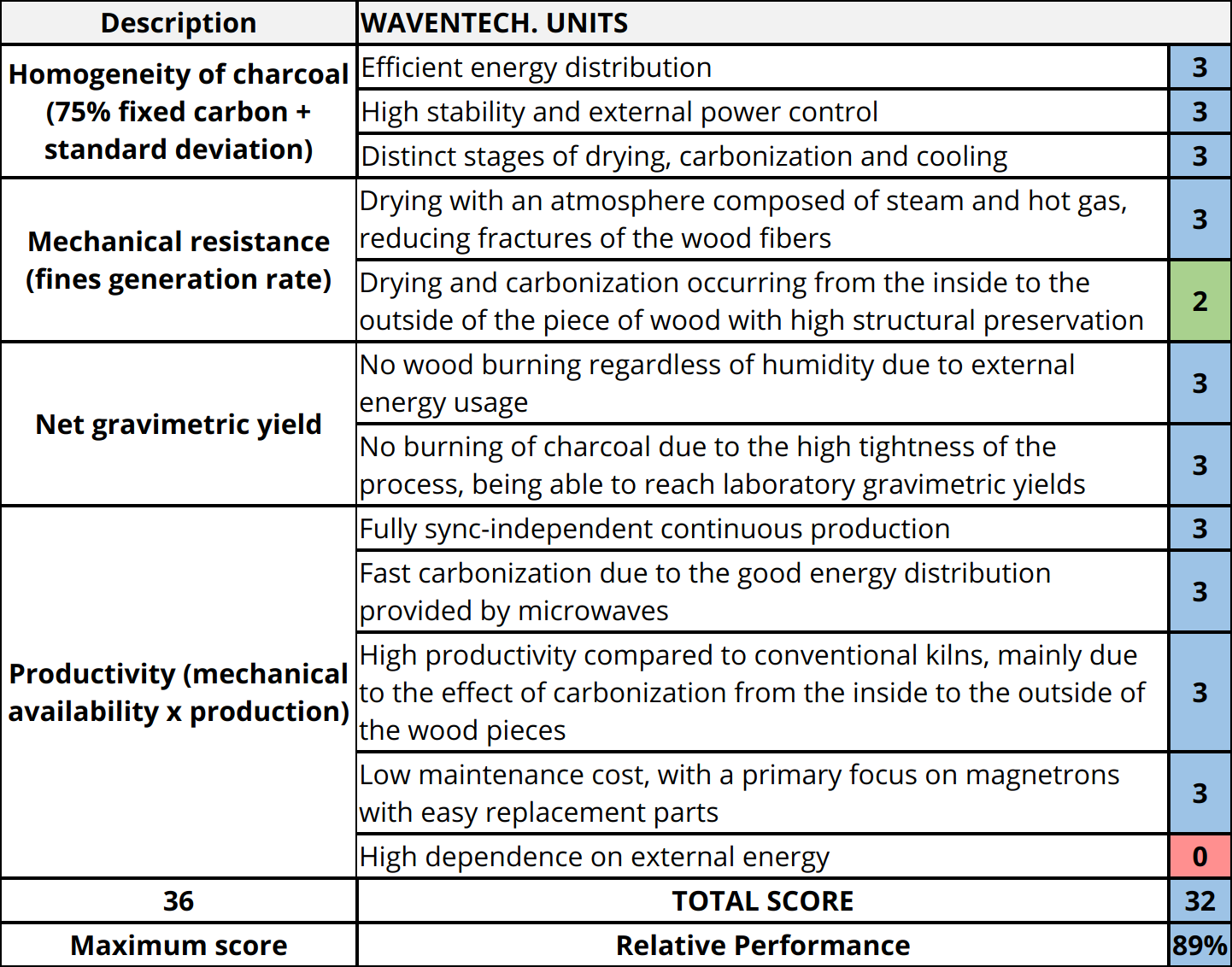

WavenTech. technology/Ondatec was evaluated by the CGEE (Center for Management and Strategic Studies) of the MDIC (Ministries of Development, Industry and Commerce) in 2014 and obtained the best evaluation among the evaluated technologies. It obtained a relative performance of 89% against 31% in relation to rectangular mansory kiln.

| Description | WAVENTECH. UNITS | ||||

| Homogeneity of charcoal (75% fixed carbon + standard deviation) | Efficient energy distribution | 3 | |||

| High stability and external power control | 3 | ||||

| Distinct stages of drying, carbonization and cooling | 3 | ||||

| Mechanical resistance (fines generation rate) | Drying with an atmosphere composed of steam and hot gas, reducing fractures of the wood fibers | 3 | |||

| Drying and carbonization occurring from the inside to the outside of the piece of wood with high structural preservation | 2 | ||||

| Net gravimetric yield | No wood burning regardless of humidity due to external energy usage | 3 | |||

| No burning of charcoal due to the high tightness of the process, being able to reach laboratory gravimetric yields | 3 | ||||

| Productivity (mechanical availability x production) | Fully sync-independent continuous production | 3 | |||

| Fast carbonization due to the good energy distribution provided by microwaves | 3 | ||||

| High productivity compared to conventional kilns, mainly due to the effect of carbonization from the inside to the outside of the wood pieces | 3 | ||||

| Low maintenance cost, with a primary focus on magnetrons with easy replacement parts | 3 | ||||

| High dependence on external energy | 0 | ||||

| 36 | TOTAL SCORE | 32 | |||

| Maximum score | Relative Performance | 89% | |||

Qualitative analysis of WavenTech. technology / Ondatec (source: Charcoal Production Modernization Report – CGEE/MDIC – 2014, page 36)

This study points out as a weak point the high dependence on external energy, but this is supplied by generation with pyrolysis effluents, producing enough energy for the carbonization plant and with a net surplus of 2.8 MWh/ton of charcoal produced.

The conventional carbonization process basically produces charcoal and smoke composed of a mixture of non-condensable and condensable gases, called bio-oil (tar and pyroligneous acids). Conventional technology for the production of industrial charcoal does not favor the use of gaseous effluents due to the following factors:

It is necessary to inject air to burn the wood and part of the smoke

It is a batch process, with no continuous smoke production

Inefficient process control produces charcoal with different fixed carbon contents, resulting high variability in the gas composition

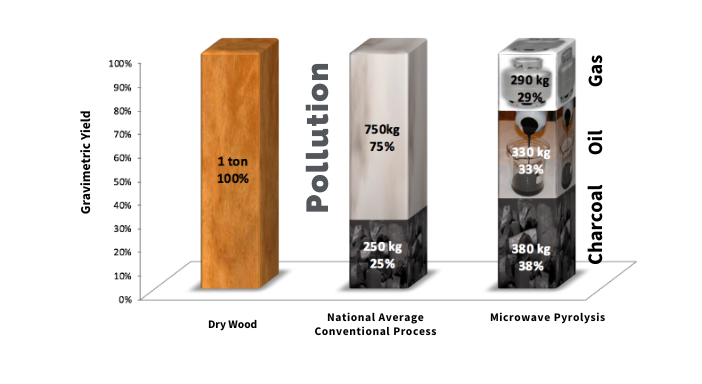

Thus, in the conventional process, one ton of anhydrous wood is converted on average into 250 kg of charcoal and 750 kg of smoke!

The pyrolysis of wood, compared to carbonization, has the advantage of making full use of the energy contained in the wood, where:

The process takes place in a controlled atmosphere in the absence of oxygen

Smoke has a higher caloric value due to the absence of nitrogen, since there is no air intake

Does not burn part of the fired wood, allowing to obtain a higher yield in wood/charcoal conversion

No effluents are released into the atmosphere, as the smoke is split into two energetic compounds: Non-Condensable Gas and pyrolysis oil (bio-oil)

The figure below illustrates the comparison between carbonization and pyrolysis:

Difference in terms of gravimetric yield

Summary of the advantages of microwave-assisted pyrolysis in charcoal production:

Clean process: no dust, no smoke and no fumes, taking place inside a closed chamber

In terms of total emissions, WavenTech. technology emits 56% less than conventional processes, or 1,124 kg less CO2 per ton of charcoal produced

There is no air injection, obtaining a higher caloric value of the effluents, with 100% utilization

Advanced process control allows obtaining defined and stable properties (fixed carbon set point), impossible in batch systems

Continuous process lasting 3 hours, without the need of synchronizing kilns

Very low ash and fines content

Improves the financial return for the pig iron chain: increased forest productivity (smaller planted area) and blast furnace

The energy required for its operation can be generated from the pyrolysis effluents

WavenTech. Technology

Comparison and Summary of Advantages

The table below makes a point-by-point comparison of the most relevant aspects in the analysis of charcoal production, related to the environment, process efficiency, yield and economy:

Point-by-point comparison: traditional method x WavenTech. technology

WavenTech. Technology

Mass and Energy Balance

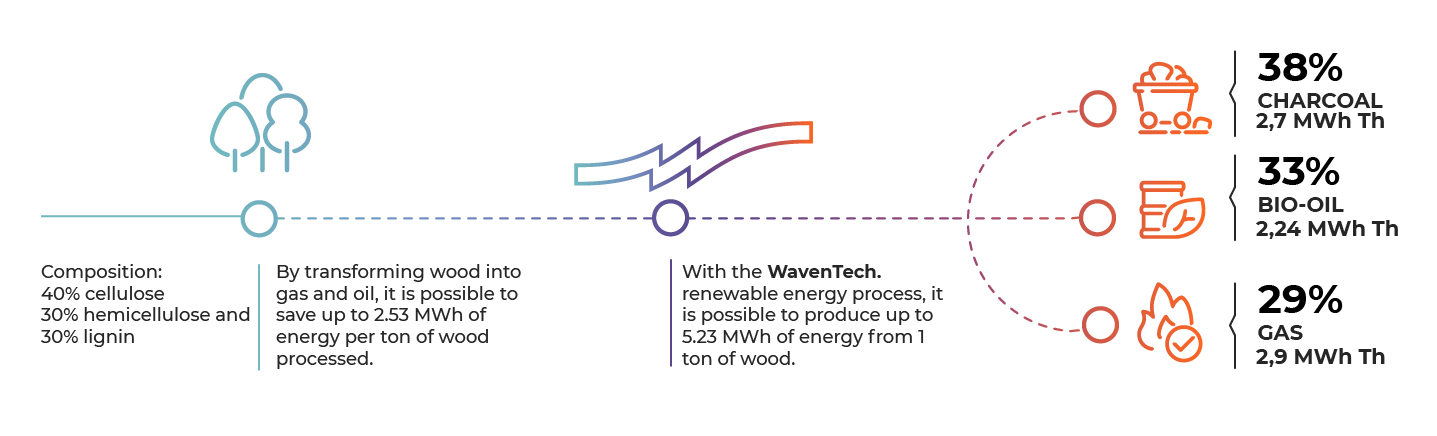

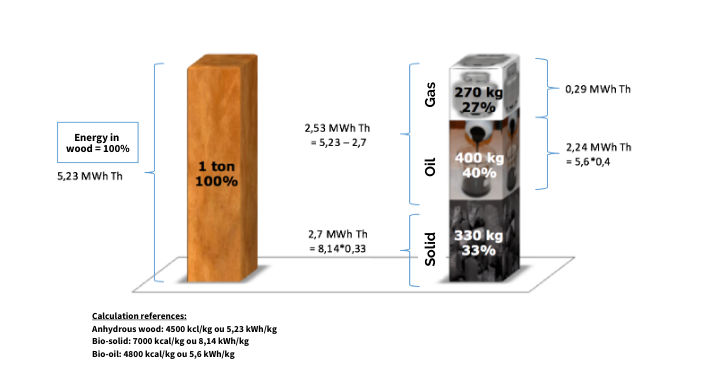

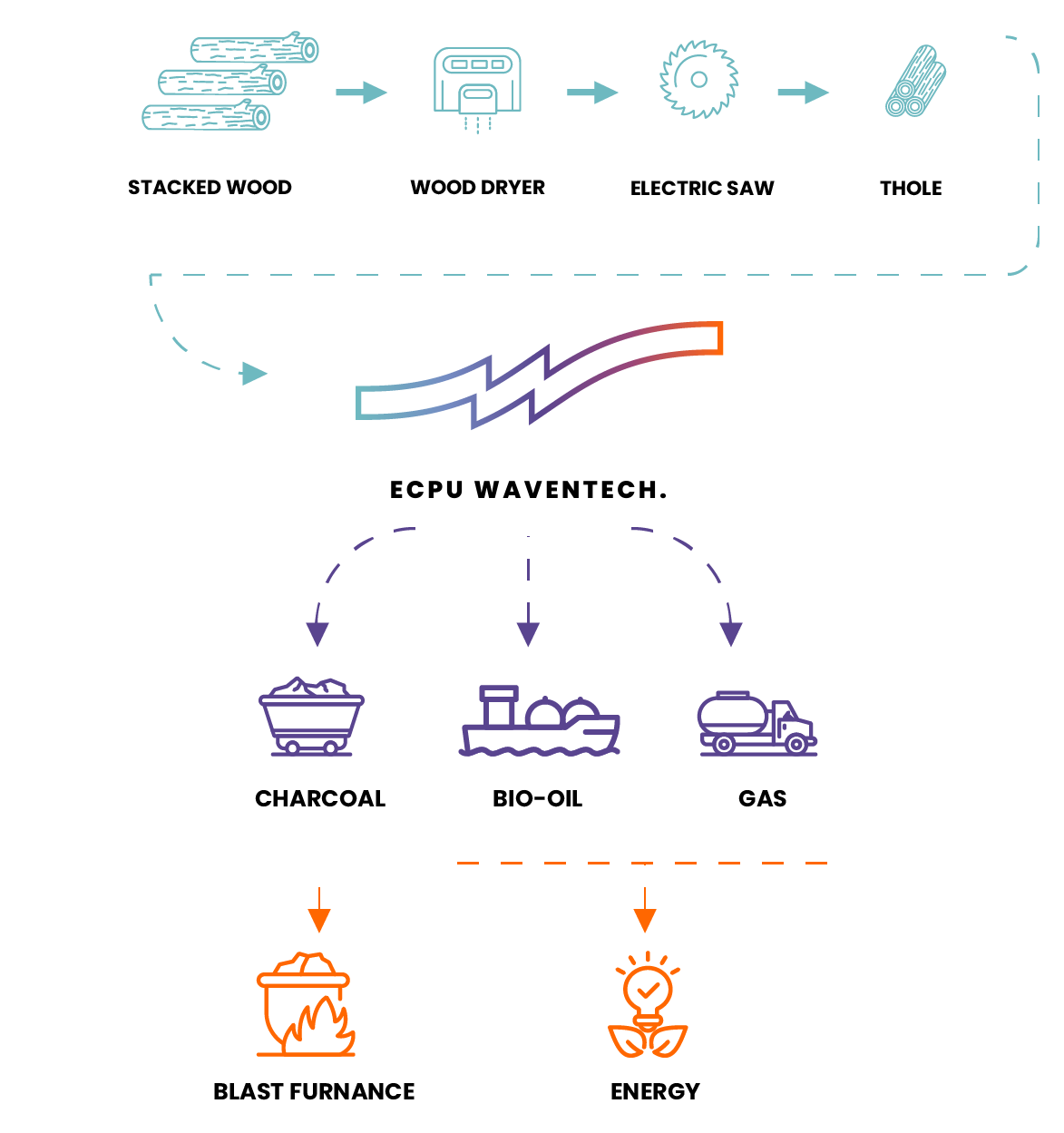

The following figure shows the carbonization products resulting from the use of the technology:

Products from the carbonization of 1 ton of wood

For each ton of charcoal, around 1.2 tons of bio-oil and 0.8 tons of Non-Condensable Gas are produced, which may vary depending on the desired fixed carbon content in charcoal. As an example, for a gravimetric yield setting of 33%, 40% pyrolysis oil and 27% CNG will be produced, as shown in the following figure:

Mass and energy balance

In terms of mass balance, it is possible to notice that the amount of thermal energy in the effluents is of the same order as that contained in charcoal, something that differs completely from conventional carbonization. It can be noted that the pyrolysis effluents, for this set point of the process, contain 48% of the original energy of the wood, which is neglected in the other carbonization processes due to technological limitations.

Less than half of the energy generated by the effluents is enough to generate electricity for the process, with a surplus of oil or electricity.

As the evaluated process is continuous and the production cycle is 3 hours, the mass flow of smoke is more than 120 times greater than in the traditional industrial kiln. And the energy density is 4 times greater because the presence of nitrogen is virtually zero (no air intake).

Burning of smoke from the microwave-assisted pyrolysis process during the continuous production of charcoal

WavenTech. Technology

Process Flow

The complete charcoal production process with WavenTech. technology, and the use of pyrolysis effluents to produce energy, is shown on the side:

Charcoal and energy production

WavenTech. Technology

Energy Consumption and Generation

The consumption of electrical energy for the production of a ton of wood can vary depending on the adjustment of the gravimetric yield. This variation reflects the desired quality of the charcoal: the lower the gravimetric yield, the higher the carbon content and the lower the mechanical strength.

The use of energy from effluents can be carried out in the following ways:

Direct burning of CNG (Non-Condensable Gas) and oil in boilers for steam generation and cogeneration of electricity

Direct burning of CNG in a gas generator

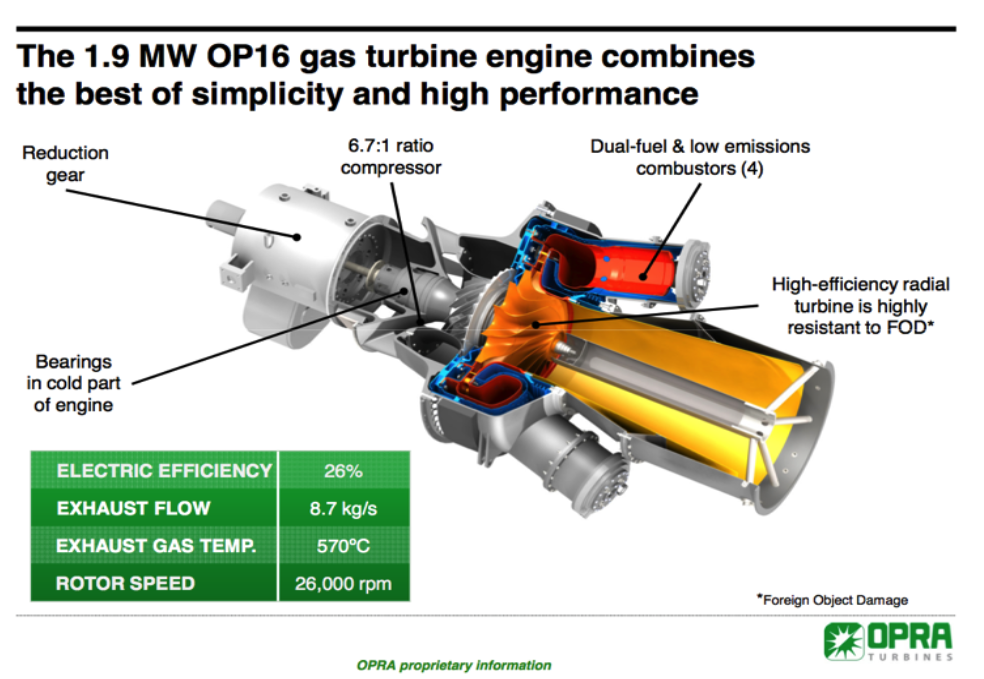

Direct burning of CNG and oil in gas turbines (OPRA turbine – OP16 developed specifically for pyrolysis oil), producing electricity and gas heated to 570°C

Turbine OPRA OP16, able to work with gas and oil from the microwave

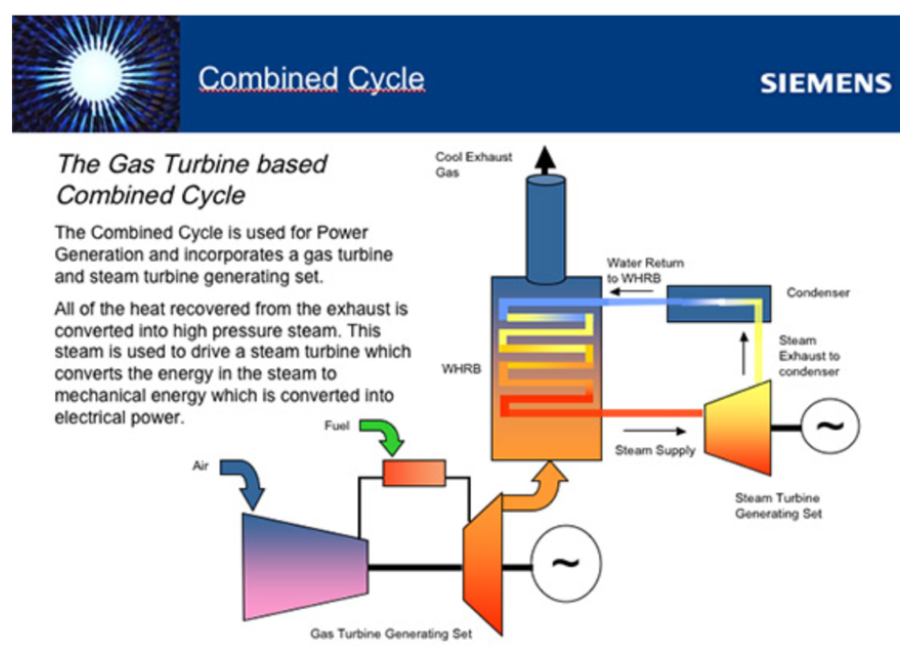

As the exhaust gases have high temperature, it is still possible to direct them to a heat recovery boiler, generating steam for another turbogenerator. This combination is excellent, as it makes the use of effluents economically viable. It is known that energy generation with biomass is only viable if it is associated with the generation of process steam, because of the low yield in the conversion of thermal energy into electricity.

The combined cycle allows significant gains. This implies lower expenditure on raw materials, lower freight costs and lower investment compared to a conventional process.

Combined cycle power generation technology is widespread using natural gas, but pyrolysis technology allows it to be applied to charcoal production. Only two elements were missing: the pyrolysis reactor (WavenTech.) and the gas turbine (OPRA) for pyrolysis gas, both already on the market!

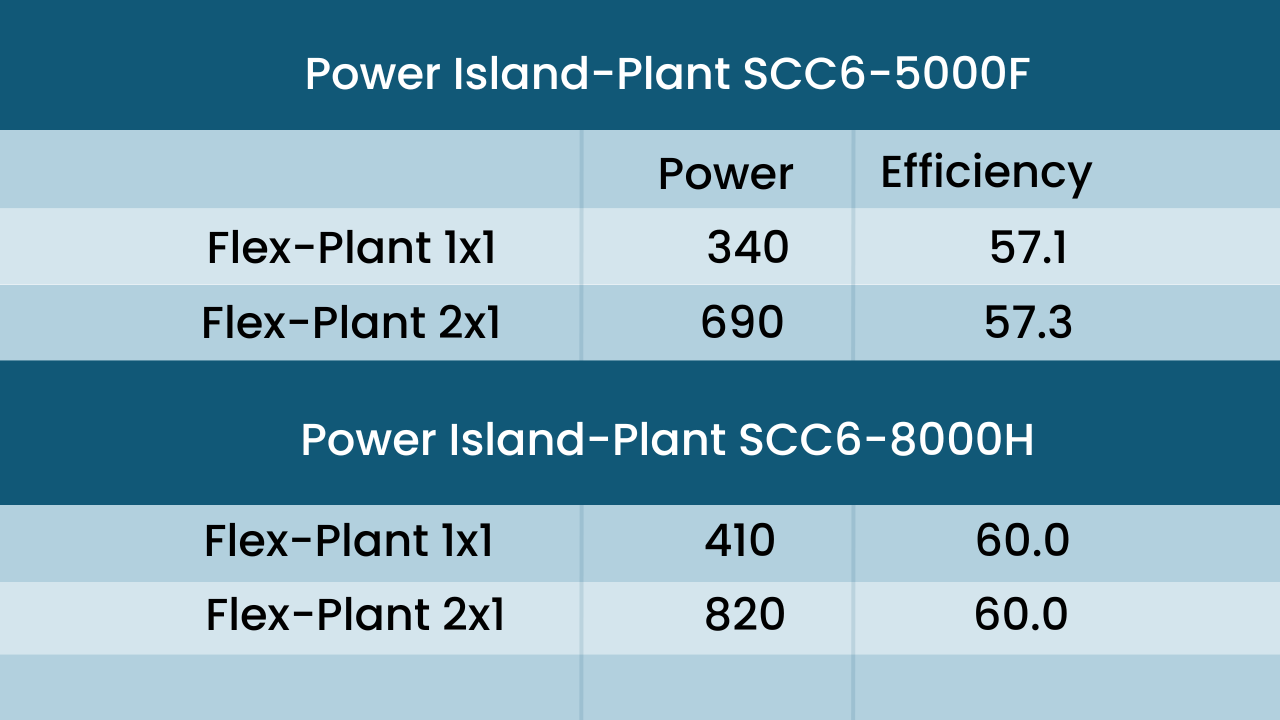

Brayton/Rankine combined cycle technology: example of Siemens “Flex-Plant”

Efficiency in the energy conversion of the Siemens “Flex Plant” combined cycle

WavenTech. Technology

Why is it disruptive?

There are a number of factors that differentiate WavenTech. technology of traditional methods, as already described.

However, certain technical peculiarities make the technology unique, compared to competitors that intend to produce charcoal in an “advanced” way, but that do not achieve the same sophistication, and consequently the same results. The differentials that guarantee the disruptive character are the following:

Babassu charcoal, produced with WavenTech. technology

The carbonization process is mathematically modeled, being able to carry out the pyrolysis of wood or any other biomass

The carbonization control is fully electric, allowing unique refinement of the parameters, exclusive to this technology

The logic of the interaction between the carbonization and process control software is the core of the technology: the hardware control system is fed back by multiple states, while the carbonization software generates the ECPU set points. In practice, once the characteristics of the wood (or biomass) are entered, this control ensures that the desired outputs are obtained (products), making the system properly deliver the power level in each magnetron and/or sector of the chamber, with the correct belt speed, while continuously monitoring all parameters