ECPU

Each Energy and Charcoal Production Unit (ECPU) is composed of the following main systems, described below:

ECPU – Energy and Charcoal Production Unit

Pyrolysis Reactor

Consisting basically of a closed chamber, equipped with a metallic belt of continuous movement and with a set of magnetrons (units of microwave emissions) in the upper part, it is where the pyrolysis reaction takes place.

Pyrolysis reactor

Unloading

ECPU – Energy and Charcoal Production Unit

Unloading

Final portion of the reactor, where the newly produced charcoal is collected in buckets, containers, big bags, etc.

Unloading

ECPU – Energy and Charcoal Production Unit

Capture of Gases / Effluents and Condensation

All the gases produced during the process are captured by an exhausting system, being conducted to a condensation apparatus that separates the liquid from the gaseous fractions. All effluent is recovered.

Therefore, there is no emission of greenhouse gases, as no CH4 (methane) or CO (carbon monoxide) are released to the atmosphere.

Condensation system

Sistema de condensação

Supervisory system screen

ECPU – Energy and Charcoal Production Unit

Control Panel

The Control Panel is actually an interface with an advanced mathematical model of biomass carbonization, allowing the insertion of specific wood characteristics in order to obtain specific parameters, such as fixed carbon.

With intuitive operation, it facilitates the training of operational staff, within a modern and safe industrial environment.

Supervisory system screen

ECPU – Energy and Charcoal Production Unit

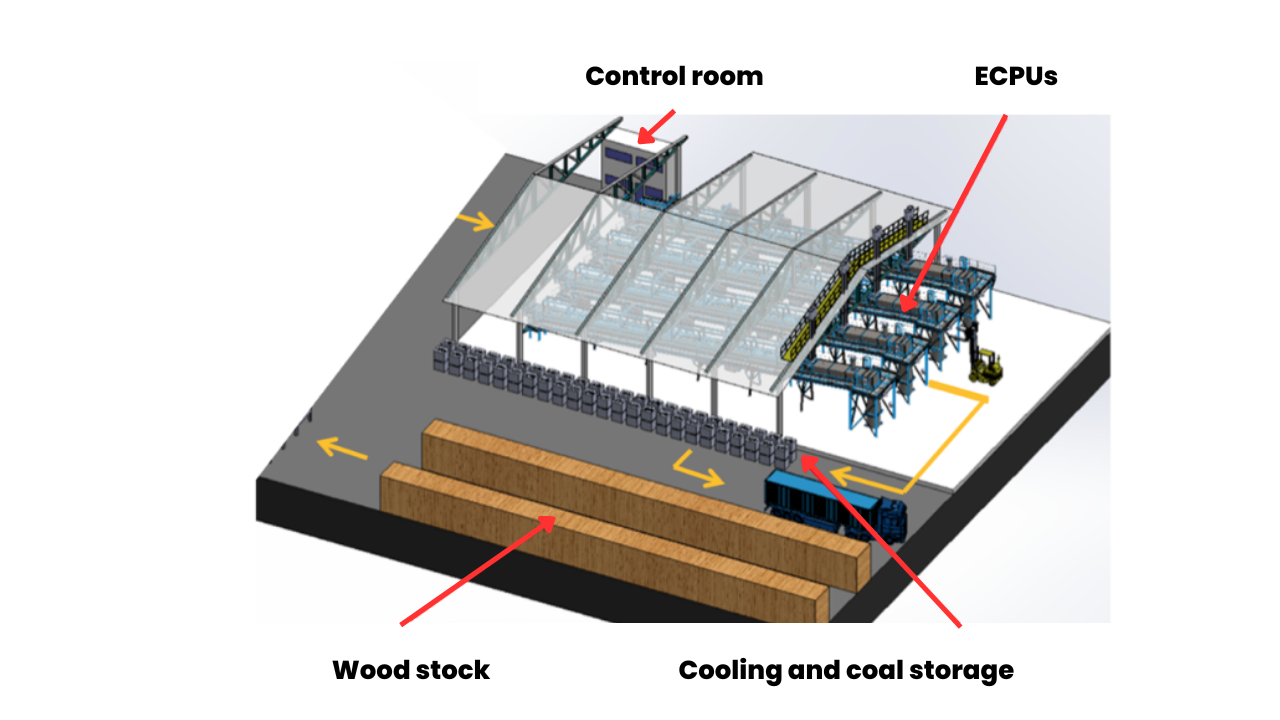

General Layout

The basic setup of a WavenTech. charcoal production plant is shown below:

control room, ECPUs, wood storage, cooling and charcoal storage

Basic layout of a WavenTech. charcoal production plant

Basic layout of a WavenTech. coal production plant

In the example above, 4 ECPU’s are presented, but being a flexible and modular system. The configuration depends on the amount of charcoal you want to produce.

The complete industrial unit consists of the following systems:

ECPUs and subsystems described earlier

Wood loading system

Coal unloading system

Compressed air system

Wood pre-drying system

Saw for cutting wood and preparing tholes

Electrical panels, with connections to the grid

Container for the monitoring room

Tanks for temporary oil storage

Forklift

Turbine for energy production with pyrolysis effluents (optional – there is the possibility of direct connection to the electrical grid and energy acquisition)